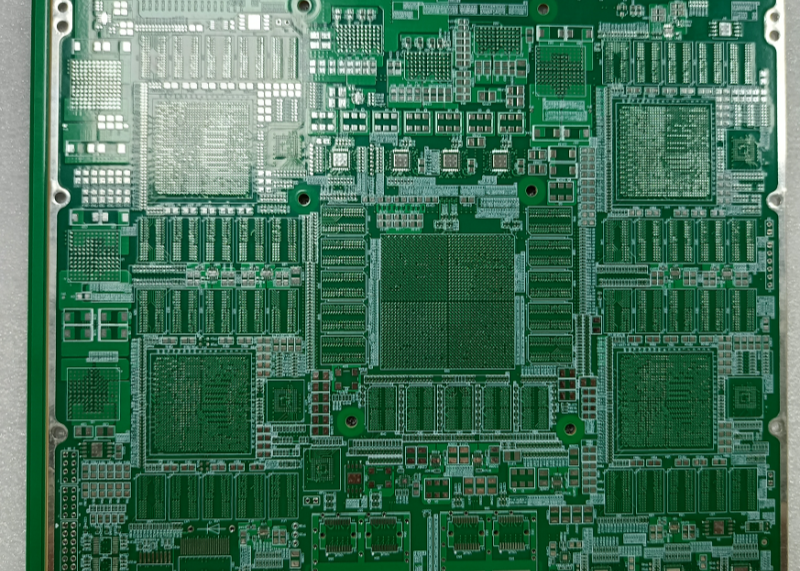

12-Layer High-Frequency PCB board

This 12-layer high-frequency PCB board is constructed using Panasonic M6 material, known for its excellent electrical properties and low transmission loss. The board measures 168 x 204 mm and features a hot air solder leveling (HASL) surface finish.

Welcome your inquiry

12-layer high-frequency PCB board Introduction

A 12-layer high-frequency PCB board constructed using Panasonic M6 material is designed for high-performance electronic applications where signal integrity, low-loss, and high-frequency performance are critical.

Specification

| Material: | Panasonic M6 |

| Layers: | 12 Layers |

| Dimensions: | 168 x 204 mm |

| Surface Finish: | HASL (Hot Air Solder Leveling) |

| Technical Challenge: | Line Width/Spacing – 3mil/3mil |

Product Feature

One of the most challenging aspects of designing and manufacturing high-frequency PCBs is achieving tight line width/spacing. In this case, the required line width and spacing are 3 mil(0.076 mm), which presents several challenges:

Signal Integrity As the line width and spacing become smaller, the electrical signal integrity** becomes more susceptible to noise, crosstalk, and interference. Ensuring that the signal flows reliably through these narrow traces requires careful design and precise manufacturing capabilities.

Manufacturing Precision Achieving such fine line width and spacing requires high-precision manufacturing processes. The capability to consistently create traces as narrow as 3 mils with proper spacing demands advanced photolithography, etching, and plating techniques. Any deviation in these dimensions could lead to short circuits or signal distortion.

Impedance Control In high-frequency applications, maintaining proper impedanceacross the PCB is crucial. With tight line widths and spacing, impedance control can become more difficult, especially in multilayer designs. Ensuring that each trace maintains the correct impedance is critical for minimizing signal reflection and loss.

Thermal Management High-density PCBs with tight trace patterns may also face challenges in heat dissipation. More components packed into smaller spaces can cause localized heat buildup, which can affect the performance and reliability of the board, especially in high-frequency applications. Thermal vias and other heat management techniques may need to be incorporated into the design.

Applications

This type of 12-layer high-frequency PCB is typically used in advanced communications systems, such as:

- Telecommunication Equipment

- Radar Systems

- Satellite Communications

- Medical Devices** (e.g., MRI machines)

- High-Speed Data Transfer** Applications

- Automotive Electronics (for high-frequency signal processing)

Product Performance

The 12-layer high-frequency PCB board with Panasonic M6 material, featuring a HASL finish and 3mil/3mil line width/spacing, is designed for high-precision, high-speed applications. The board’s multi-layer construction, combined with the ability to handle tight manufacturing tolerances, makes it ideal for use in demanding environments where signal integrity, durability, and precision are paramount. However, the technical challenges posed by such fine line widths and spacings require advanced fabrication techniques to ensure optimal performance and reliability in high-frequency operations.

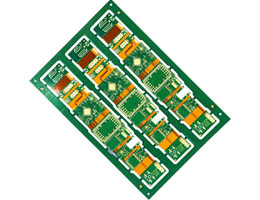

Related Products

This 4-layer hybrid rigid-flex PCB combines the best of rigid and flexible circuit technologies, enabling breakthrough designs for modern consumer electronics. Perfect for applications where space constraints, reliability, and innovative form factors are